Prodcuts

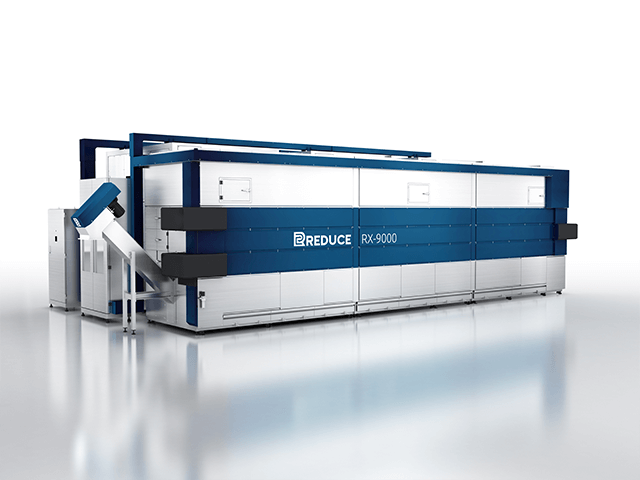

RX series

Dryer

- Suitable for continuous processing and highly automated applications

- Highly customizable inlet and outlet equipment and peripheral devices, with sensor-based adjustment for flexible and intelligent feeding, capable of handling large quantities of sludge.

- Equipped with multiple intelligent security features, it can seamlessly connect upstream and downstream processes to achieve stable, synchronized control.

- The independently developed dedicated heat pump and exclusive patented closed-loop air duct design result in excellent air density and high drying efficiency.

- Built-in pulse device for regular cleaning of filter cartridges, maintaining air permeability and drying efficiency, reducing labor maintenance costs.

- The drying chamber features a special conveyor design that is easy to disassemble and maintain, has strong load-bearing capacity and is durable, and also prevents material accumulation inside.

Specification

RBC Series

Batch dryer

- Suitable for batch processing

- Extremely easy to operate, can process small amounts of sludge in stages.

- Small footprint, space-saving, flexible configuration depending on factory size

- Highly customized drying material feeding trolley and peripheral equipment

- Built-in pulse device for regular cleaning of filter cartridges, maintaining air permeability and drying efficiency, reducing labor maintenance costs.

- The integrated and modular design is optimized, resulting in excellent air density and high drying efficiency while also maintaining flexibility in equipment setup.

Specification

- Note 1The daily water removal capacity is estimated to be at a standard state where the sludge moisture content is 80% to 40%, and the trolley needs to be replaced approximately 2-3 times per day.

This data is related to the characteristics of the customer's sludge. For detailed calculations, please contact the distributor and provide samples for further discussion. - Note 2Energy consumption estimation under standard conditions, with sludge moisture content decreasing from 80% to 40%, based on operating data over eight hours.

- Note 3Depending on the characteristics of the sludge and the need to adjust drying energy consumption, the drying temperature may fluctuate and is not positively correlated with the water removal capacity.

- Note 4The dimensions are preliminary reference values for the area occupied. Due to equipment updates and version changes, there may be slight differences from the actual dimensions.

Customizations can be made within a reasonable range based on the customer's actual situation. Please contact the distributor for details. - Note 5The power requirement is the rated capacity; energy consumption assessment should be based on actual usage conditions.

Dryer

Continuous dryer, batch dryer, combined dryer

Applications

Industrial waste

Food factory waste sludge

Electroplating waste sludge

Textile industry waste sludge

Raw material drying

dried fruit

corn

tea

mushroom

okara

FAQ