Heat pump drying

Add InquiryContinuous heat pump sludge dryers are equipment that can operate for extended periods.

The sludge is continuously fed in for drying and is discharged after a certain period of time, reaching the required dry state.

In addition, after starting the equipment, personnel only need to ensure that the sludge flows in and out smoothly, without needing to perform complicated operations on the equipment.

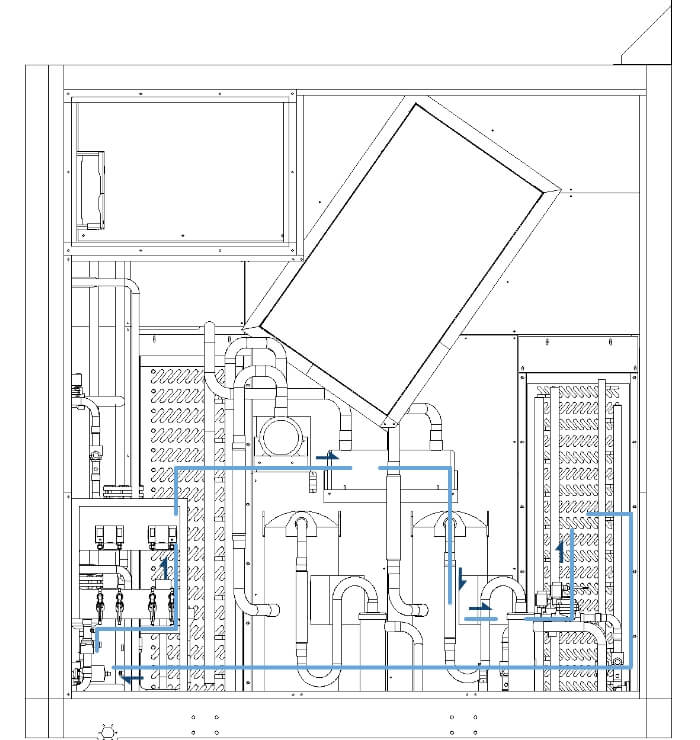

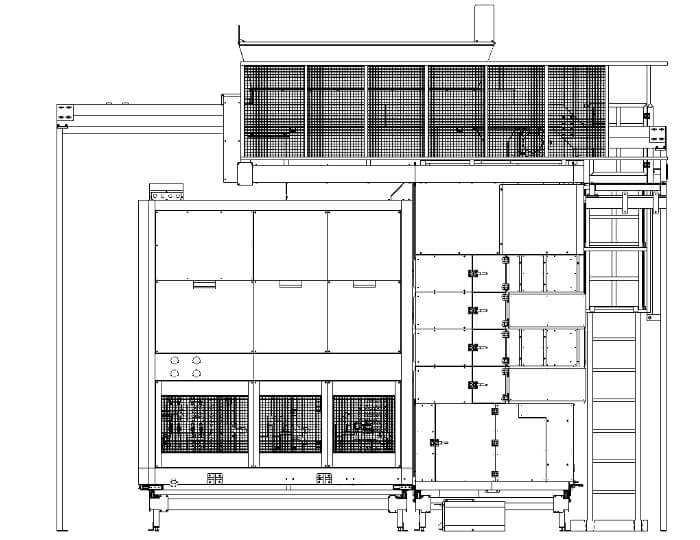

The equipment mainly consists of three cycles: sludge drying cycle, air cycle, and refrigerant cycle.

Sludge dryers are typically installed at the end of the wastewater treatment process. Therefore, before the sludge enters the dryer, there is the issue of how to transport it to the loading point. This part is mostly customized according to the customer's specific site conditions. The process of transporting the sludge to the loading trough is considered entering the equipment.

The sludge feeding trough mainly consists of two components: a mixer and a sludge spreader. Their primary function is to evenly distribute the sludge onto the conveyor rack, ensuring that the sludge particles are of stable size, have an even thickness on the rack, and have sufficient gaps.

Once the sludge enters the conveyor rack from the feed hopper, the drying process begins. From entry into the equipment until drying is complete and the sludge is output, it takes approximately 1.5 to 2 hours. Therefore, the conveyor rack operates very slowly and steadily. The standard number of conveyor racks is three, but this can be increased or decreased according to customized requirements.

Once the sludge has dried, the way it is output from the equipment will vary depending on the customer's requirements. A common method is to use a screw conveyor to output the sludge, such as a bag or a container.

Assuming the required operating environment for drying is 65°C, and taking the removal of 1 kg of water as a baseline, the latent heat of vaporization of water is approximately 560 kcal/kg. Since the heat required for water evaporation during the drying process is 60% - 70%, the total heat required to dry 1 kg of water is 800 kcal.

| Compare Projects | heat pump | electric boiler | Oil-fired boilers | gas boilers |

| Energy | electricity | electricity | fuel oil | natural gas |

| Calorific value (A) | 860 calories/degree | 860 calories/degree | 9120 kcal/L | 8000 calories/m³ |

| Thermal efficiency (B) | 400% | 95% | 65% | 75% |

| Effective calorific value (A*B) = (C) | 3440 calories/degree | 817 calories/degree | 5928 kcal/L | 6000 calories/m³ |

| Energy requirement of 800 calories (D) 1-[(C-800)/C] | 0.23 degrees | 0.98 degrees | 0.135 L | 0.133 m³ |

| Energy price per unit (E) | 3$/degree | 3$/degree | $18.6/L | $15/m³ |

| Energy costs (D*E) | 0.69$ | $2.94 | $2.51 | $2.00 |

| Security | Very high | Electric heating, piping, leakage | Oil leak, explosion, fire | Oil leak, explosion, fire |

| Environmental protection | Pollution-free | Pollution-free | Oil stains and exhaust fumes | greenhouse gas emissions |

| Service life (years) | 10-15 | 5-8 | 6-9 | 6-9 |

It only requires power to the compressor and uses the working fluid conversion process to transfer ambient heat energy, saving about 75% more energy than ordinary electric heating.

The equipment does not require additional installation of electric heating, fuel/gas pipelines, etc., and there are no hidden dangers such as leakage or fire. Moreover, the maintenance cost is low.

The heating process generates no waste or emissions, and the internal working fluid (refrigerant) can be sustainably recycled.

No additional pipeline maintenance is required, and the equipment lifespan can reach 10-15 years depending on the compressor usage.